four. Regime Inspection and Tests: Regular inspection of door interlocks, ventilation systems, and other parts is vital for sustaining the operation in the airlock. Testing need to be done periodically to make sure all systems operate as made.

Increased Safety: Safety is paramount, and air locks add noticeably to it. They call for personnel to use the proper cleanroom apparel just before stepping into a cleanse area, minimizing the chance of introducing outside contaminants. It’s an easy but productive approach to copyright cleanliness benchmarks.

In Pharmaceutical, Bio-Pharmaceutical and thoroughly clean assembling, the cleanse room condition is the actual essential for all assembling action: without having a legitimate development instrument and foundation affliction, no drug can be made for persistent utilization.

Airlocks need to be devoted to certain merchandise strains if cross-contamination is a concern, specifically in environments dealing with harmful or powerful products. Nonetheless, airlocks is often shared in some cases, furnished thorough decontamination procedures are in position concerning product changeovers.

OSD production airlocks are especially created for the production of oral strong dosage varieties e.g. tablets and capsules.

Sustaining a sterile ecosystem is key to profitable fermentation. Before beginning the procedure, sterilize your fermentation vessel, airlock, and any other tools you’ll be making use of. This decreases the potential risk of unwelcome microorganisms interfering With all the fermentation approach.

The valuable micro organism developed in the course of fermentation website are highly effective probiotics that boost a balanced and numerous gut flora.

3. Sizing and Format: The size and format from the airlock have to accommodate the staff or supplies that can go through it.

Sink Air Lock: This type operates at a lower tension when compared with the spots close to it. By pulling air in from each side, it produces a barrier that retains contamination out. You’ll normally locate this in spots addressing hazardous substances.

In sink more info airlock, the stress inside airlock is detrimental As well as in adjacent locations tension is favourable so air moves from better tension area to reduce tension area mean from adjacent rooms to the airlock.

Airlocks happen to get among the finest solutions to mitigate this chance, which describes why they’re so normally Employed in these environments. In the following paragraphs, we’ll take a look at what cleanroom airlocks are, how they work, the different types, and more.

1. Cleanliness Classifications: The airlock have to be built in accordance with the cleanliness amounts of the adjacent rooms.

Entryways of your airlocks must be available to better excess weight side which assist to shut the entryway.

These airlocks are quite common having greater stress on a single side and reduce stress on An additional side. Within this system, constructive air pressure flows from the higher inner zone towards the airlock and from the airlock to your lesser decrease pressure quality region

Alicia Silverstone Then & Now!

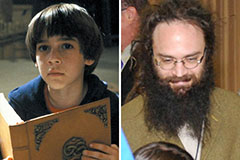

Alicia Silverstone Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now!